What are the physical limitations of magnetic storage on HDDs, and how do manufacturers overcome them?

- Thermal Gradient: As HDDs operate, thermal gradients can cause changes in the magnetic properties of the recording layer, leading to reduced storage density and reliability.

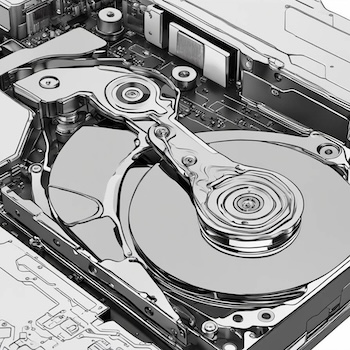

- Physical Damage: The delicate components within HDDs, such as the read/write head and spinning platters, make them susceptible to damage from impacts or temperature changes.

- Mechanical Wear: The mechanical nature of HDDs contributes to longer access times and potential performance bottlenecks.

- Data Retention Requirements: Magnetic storage devices store data for varying periods, from temporary to long-term, which affects their design and manufacturing.

- Recording Density: As HDDs aim for higher storage capacities, they face limitations in recording density due to the physical constraints of the magnetic media and read/write head design.

Manufacturers’ Approaches to Overcome Physical Limitations

- Perpendicular Recording (PMR): Introduced in 2005, PMR technology magnetizes the recording layer in opposite orientations, reinforcing each other, and is used in certain HDDs.

- Bit-Patterned Media (BPM) or Discrete Track Media (DTM): These approaches aim to overcome recording density limitations by using new media structures and manufacturing techniques.

- Energy-Assisted Magnetic Recording: This technology uses additional energy sources, such as electric currents or magnetic fields, to enhance the recording process and improve storage density.

- Advanced Manufacturing Techniques: Manufacturers have developed techniques to improve the quality and consistency of the recording layer, such as using ruthenium as a separating layer, and optimizing the read/write head design.

- Redundancy and Error Correction: HDD manufacturers implement redundant data storage and error correction mechanisms to mitigate the effects of physical damage, thermal gradients, and mechanical wear.

By addressing these physical limitations and implementing innovative technologies and manufacturing techniques, HDD manufacturers have been able to increase storage capacities, improve reliability, and reduce costs, enabling the widespread adoption of magnetic storage in various applications.